Screen Printing

The Process of Screen Printing onto Clothing:

In order to create the screen, artwork needs to be supplied in vector format (eps or vector PDF) as each colour in the artwork is separated and a different screen is created for each colour that is to be printed. This is why screen printing incurs a higher set-up cost than other printing techniques.

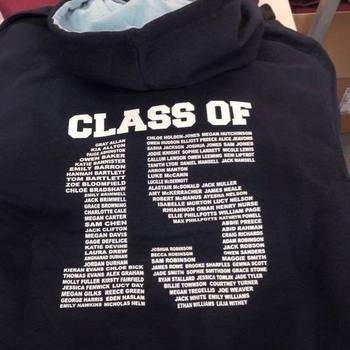

Initially, the ink is mixed to the required Pantone colour reference and applied to the screen. Squeegees are used to push ink through the mesh of the screen and onto the garment. When printing onto dark coloured garments, a white layer or flash layer of ink is applied first and then the coloured inks are applied on top of this to ensure an accurate Pantone colour match. We screen print onto T shirts, hoodies, sweatshirts, polo shirts, tote bags and many more products.

Advantages of Screen Printing:

• High quality finish

• Great for designs with multiply colours

• Long durability

• Pantone colour matching to keep true to brand guidelines

• Great for large volumes and competitively priced when ordering more

• Fastest printing technique for printing in large volumes

Disadvantages of Screen Printing:

• High set-up costs on multi colours

• Not good on smaller detail

• Not most effective for smaller quantities

• Does not work with gradient colours