What We Do

A Star Printing is a leading clothing company in the UK, specialising in printing and embroidery. We provide work of the highest quality at a price that is right! Our services and products cater for all needs and our 15 years design experience will give you endless possibilities when designing your garment.

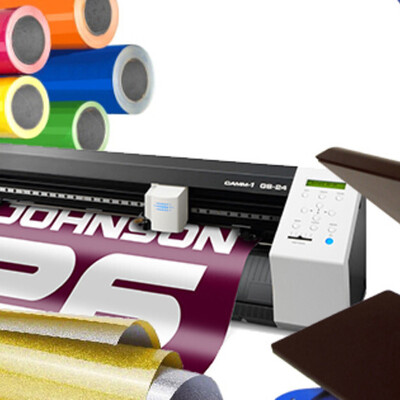

Vinyl Printing

Heat Transfer Vinyl (HTV) is a process where a PU free Vinyl Heat substrate is fed through a machine and is cad cut. The designs are created in a design program called Corel Draw. The design is then cut in reverse, weeded to reveal the design. It is then applied to the garment/product using an industrial heat press under a strict time/pressure setting. A major advantage of vinyl printing is that there aren’t any setup costs involved allowing for short print runs at a very reasonable price. It is also very versatile and can be used on virtually all types of products including T-Shirts, polo shirts, work shirts, bags, caps, workwear and lots more. The different types of vinyl allow for different specialist effects that your designs can be made from or that could be added to certain elements of your design to make it stand out from the rest. The most popular effects include glitter printing, glow in the dark, metallic printing, reflective printing and flock printing. The process of printing these special effect materials is exactly the same; a plotter is used to cut the design from the material before it is applied using an industrial heat press on to the garment itself.

DTF (Direct to Film) Printing

To produce DTF transfers we use specialist ink with a large format CMYK printer. We print directly onto a coated material PET film. Once printed the transfer is coated in a special adhesive powder, so it will adhere to any garment. The adhesive is then cured in a dryer to bond the adhesive to the DTF transfer and it is then ready to go. The transfer can then be applied to any garment with a heat press and also no pre-treatment is required.

Embroidery

Embroidery is an excellent technique as it’s great for all types of garments from corporate clothing, uniforms, workwear and any other types of clothing that you can think of. From large organisations to small businesses, embroidery is the perfect way to customise your clothing and ensure that your brand name and logo is represented perfectly. The low cost of embroidery makes it ideal for start-up companies and large organisations with a large workforce. Embroidery is a great way to add durability to your logo. In our ever-growing embroidery department, we have the best tools to reproduce high quality logos and other graphics that can be embroidered on a wide range of garments including t-shirts, polo shirts, hoodies, fleeces, caps and jackets. We use threads from the Maderia classic range, including classic rayon 40 and poly neon40.Our Melco embroidery machines work nonstop and deliver outstanding performance, efficiency and stitch quality.

Screen Printing

In order to create the screen, artwork needs to be supplied in vector format (eps or vector PDF) as each colour in the artwork is separated and a different screen is created for each colour that is to be printed. This is why screen printing incurs a higher set-up cost than other printing techniques.

Initially, the ink is mixed to the required Pantone colour reference and applied to the screen. Squeegees are used to push ink through the mesh of the screen and onto the garment. When printing onto dark coloured garments, a white layer or flash layer of ink is applied first and then the coloured inks are applied on top of this to ensure an accurate Pantone colour match. We screen print onto T shirts, hoodies, sweatshirts, polo shirts, tote bags and many more products.